You are here

StrataBond Solves Shearing Issues con't

StrataBond Solves Shearing Issues

Severe duty air disc users have frequently complained of pad shearing, where the pad separates from the backing plate due to extreme radial stress during braking.

This problem was created when manufacturers tried to solve noise issues. Simply put, high resin content formulations are required to bind the friction to the backing plate. But that excess resin can glaze the pad and cause noise issues.

In an effort to reduce noise, manufacturers used less resin and compromised the adhesive ability of the friction.

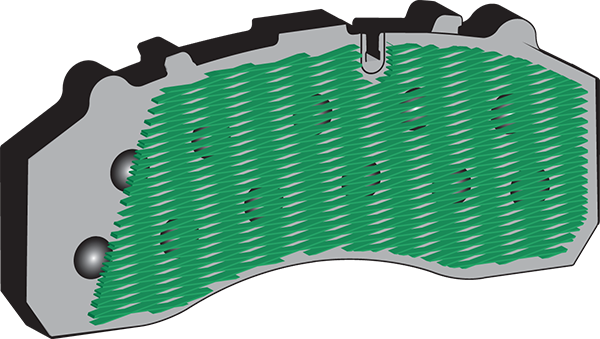

A-Line pads are built with a proprietary StrataBond® shear strength technology.

The secret to improved shear strength lies with stratified layers of encapsulated mechanical retention systems (EMRS), phenolic resin-based adhesive, a 3mm deep high-resin stabilizing layer, topped with a high-torque, low noise friction layer.

This improves shear strength up to 300% for high torque applications.

KZ2 uses the hook-based EMRS pictured above, while KZ3 and KZ6 use the half-hole and mesh-based EMRS as pictured below.