You are here

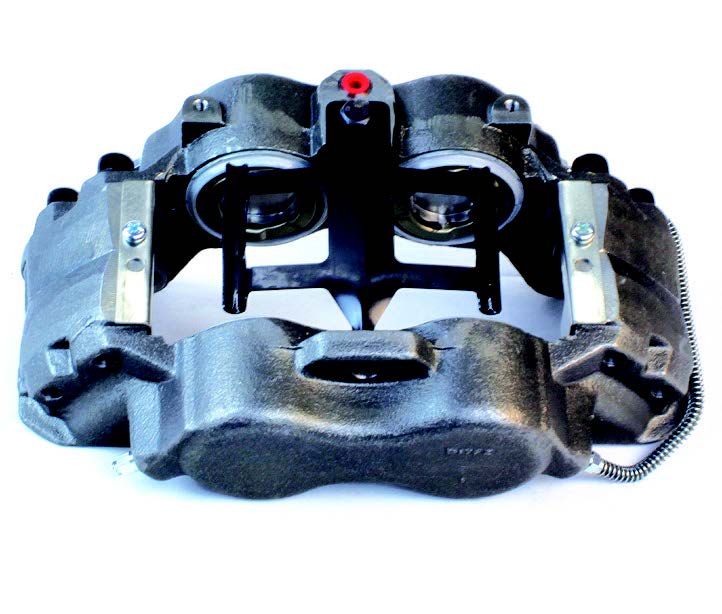

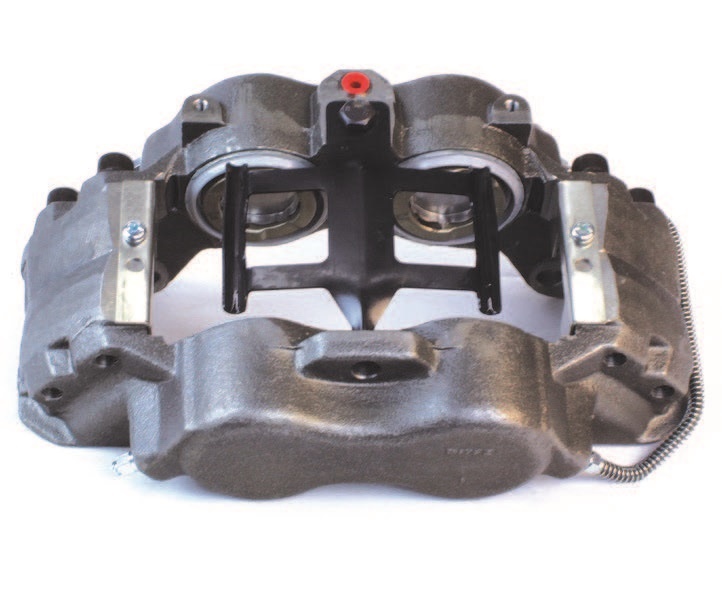

Hydraulic Calipers

Extreme Medium Duty Engineering

A-LINE’s line of medium duty calipers are engineered to be a lot more than just medium. We know the severe service that school buses, delivery vehicles and emergency vehicles demand from their hydraulic braking systems.

A-LINE’s line of medium duty calipers are engineered to be a lot more than just medium. We know the severe service that school buses, delivery vehicles and emergency vehicles demand from their hydraulic braking systems.

That’s why A-LINE uses premium grade 80,000 psi tensile strength ductile iron and application-specific pistons. Get the best of OE specs coupled with A-LINE engineering to meet your fleet’s most demanding hydraulic braking needs.

Four Features Engineered For a Better Caliper

Fleets with medium duty hydraulic braking systems know that calipers have to withstand extreme temperatures and pressures.

A-LINE spec every caliper to meet or exceed OE standards for elasticity, thermal elongation and durability.

Every caliper is cast with high tensile strength pearlite ductile iron that has an ultimate tensile strength of 80,000 psi. This specialized iron allows the caliper to withstand high heats without loss of shape in the bore that can cause piston hangup.

Every seal and boot set is made of high thermal resistant synthetic EPDM or silicone to maintain lubrication in high heat environments.

While each caliper is uniquely manufactured with aluminum, steel or phenolic resin pistons, A-LINE will provide customized pistons to meet the fleet’s individual load requirements.

Finally, every A-Line new medium duty hydraulic caliper comes with a two-year warranty against defects in parts and workmanship.

Medium-Duty Hydraulic Caliper Identification Guide

Identification In Five Easy Steps:

| SINGLE SLOT | DUAL SLOT | OPEN CAVITY |

| Bendix-Style | Akebono-Style, Bendix-Style | Dayton-Style, Meritor-Style, TRW-Style |

1. Identify the caliper by looking at the top of the caliper to determine its style.

2. Count the pistons:

Two = Akebono, Bendix, Bosch, Dayton

Four = Meritor

3. Measure the piston/bore:

| Metric (60, 66, 70, 73mm) = | Standard (2.50, 2.60, 2.88”) = |

| Akebono, Bosch, TRW or Meritor |

Bendix or Dayton |

Akebono, Bendix, Bluebird, Bosch, Dayton, Ford, Freightliner, GM, Hino, IHC, Isuzu, Meritor, Sterling, Thomas, TRW and any other brand names are the respective intellectual property of their repsective parent corporations and are used for reference purposes only. A-LINE® is a registered trademark of ACR Holdings, Inc.. The user of this information should not infer any ownership or affiliation of A-LINE® with any of the aforementioned companies or brands. ©2021 ACR Holdings, Inc. The material in this document is copyrighted any may not be distributed in any form without the express written permission of ACR Holdings, Inc.

4. Find the casting number

5. Count the bolt holes.

(Can be referred to as per side or total)

Hydraulic Caliper Part Numbers

Hydraulic Caliper Cross Reference